Gaoke Lecture Hall: Incorrect Hydraulic Hose Installation Turns into a Bomb Instantly! Must-Read "Anti-Explosion Guide"

Time of issue:2025-06-14

Hydraulic hoses are the "lifeline" of industrial equipment, delivering hydraulic oil efficiently -critical to production and safety. Improper installation can lead to anything from leaks to bursts, causing accidents!

Gaoke Lecture Hall unveils the key principles of hydraulic hose installation – each one forms a solid safeguard for equipment stability and personnel safety!

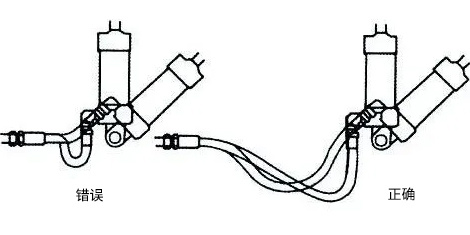

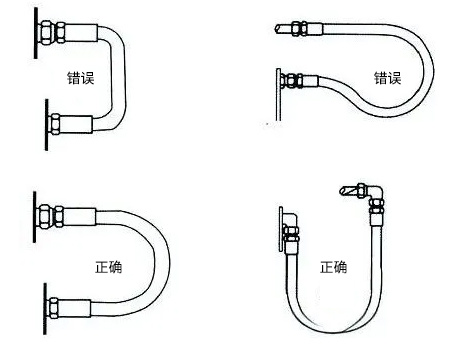

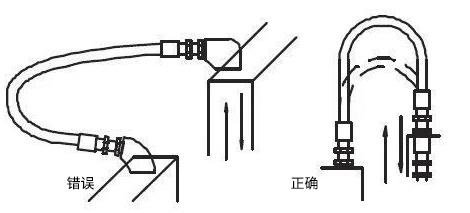

01 Avoid Twisting or Torsion

Strictly prevent twisting during hydraulic hose installation! Tests show that torsion of as little as 7° can reduce hose life by a drastic 80%. Precise installation to avoid torsion becomes absolutely critical, particularly when the connected components exhibit relative motion and the hose must bend within a single plane. Failure to do so will severely compromise the hose's pressure-bearing capacity and service life.

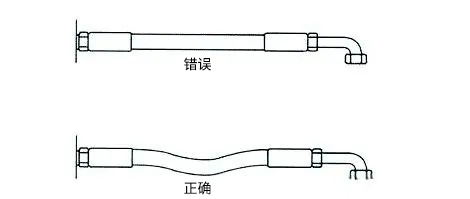

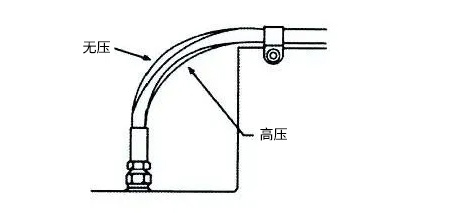

02 Provide Length Allowance

During installation, hydraulic hoses must include sufficient length allowance to accommodate pressure-induced length variation. A typical allowance of 3%–5% is recommended.

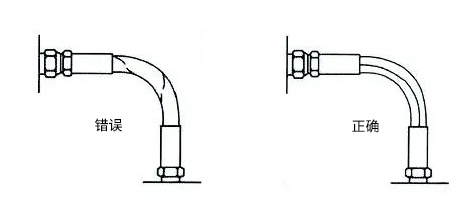

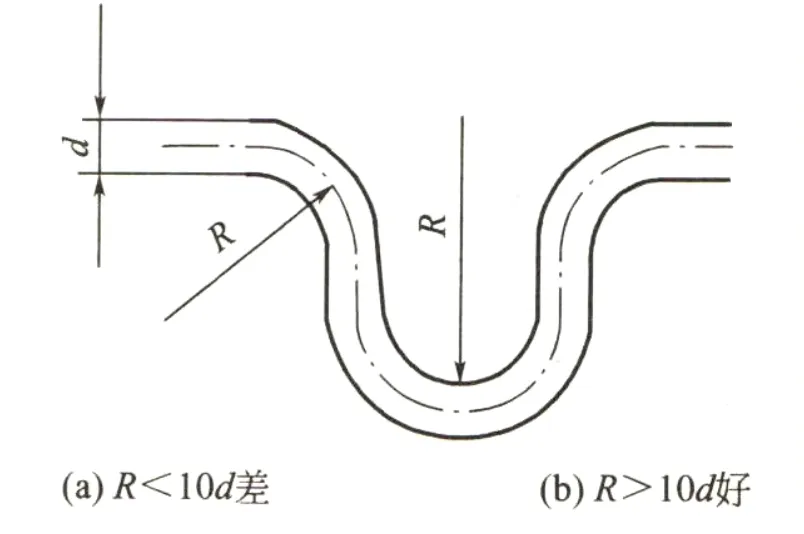

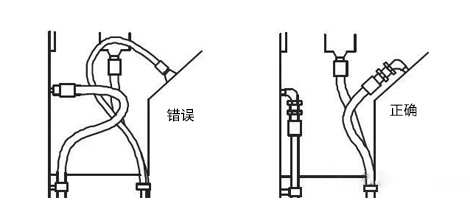

03 Maintain Minimum Bend Radius Requirements

Sharp bending strictly prohibited: Hose bend radius must not be less than 10–12× its outer diameter to prevent collapse or deformation at the bend.

No bending at fittings: A straight section ≥1.5× outer diameter must be maintained immediately adjacent to fittings.

04 Determine Correct Hose Length

Hose length selection must account for pressure-induced length variation. Avoid excessive length (incurring unnecessary cost) or insufficient length (risking rupture due to inadequate movement allowance).

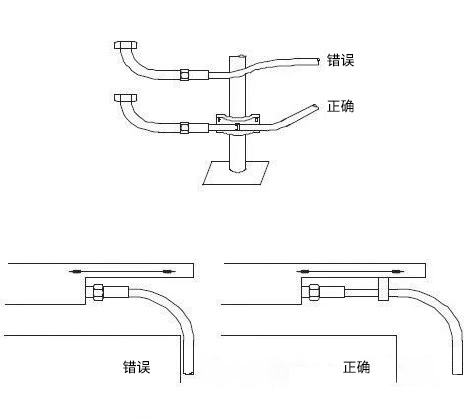

05 Critical Clamp Installation Guidelines

• Never clamp in dynamic bending zones: Clamps must never restrict hose movement in areas subject to flexing.

• Secure only on straight sections: Clamps shall be exclusively positioned on straight runs to prevent shear damage and abrasion during pressurization.

06 Prevent Abrasion Damage

Eliminate direct contact with adjacent surfaces through proper routing or protective sleeves; maintain clearance ≥2× hose OD from moving components to prevent vibration-induced wear.

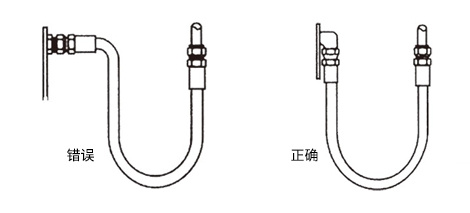

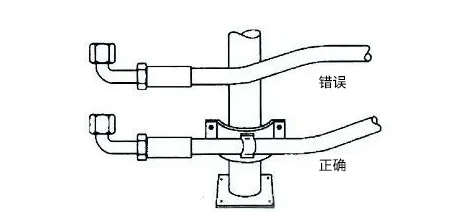

07 Select Optimal Fittings

• Maximize space efficiency: Utilize compact/angled fittings to minimize hose length and routing complexity

• Align with motion plane: Ensure fitting orientation matches hose bend plane with component movement direction

• Maintain bend radius: Select fittings preserving ≥10×OD bend radius to eliminate torsional stress

08 Maintain Thermal Clearance

Route hydraulic hoses ≥300mm from heat sources (e.g., diesel exhaust systems, turbochargers) to prevent thermal degradation. Continuous ambient temperature shall not exceed 150°C per ISO 18752 thermal aging thresholds.

Choose Gaoke Rubber & Plastics — Choose Professional Assurance! We deliver not only high-performance hydraulic hoses meeting ISO 18752 standards, but also champion scientifically validated installation protocols for operational excellence.

Tag:

Recommended News